How to use defoamer for delayed coking?

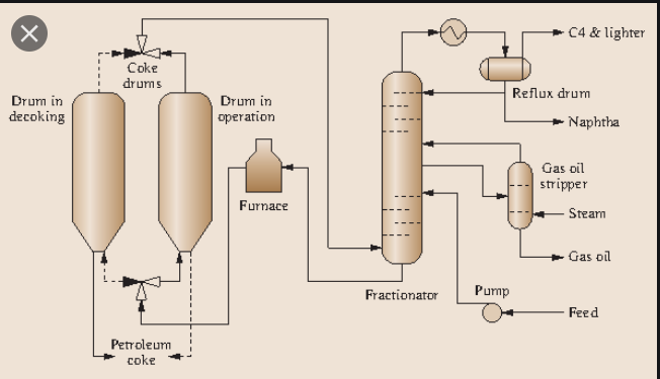

Delayed coking is a process in which heavy cracked oil is heated to undergo deep cracking and condensation reactions and converted into gas, gasoline, diesel, wax oil and coke.

During the reaction process, the coke tower can be divided into three main areas along its height:

- The lower part is a coke layer;

- The middle part is a high-viscosity colloidal asphaltene called a foam layer;

- The upper part is a hydrocarbon layer.

The foam layer will maintain a certain height under a certain temperature and pressure.

The factors affecting the height of the foam layer are:

the amount of processing, the nature of the raw materials, the exit temperature of the heating furnace and the circulation ratio. Trying to reduce the height of the foam layer is an important measure to increase the throughput. In order to achieve the purpose of reducing the foam layer, generally adopt methods such as setting a material level meter, using a foaming agent, and selecting a suitable furnace outlet temperature. Among them, the use of antifoam injection is actually a feasible and effective measure. The coke towers in foreign countries are about 3 meters in height.

In China, in order to prevent punching towers, they often reach more than 5 meters. The volume utilization rate of coke towers in foreign countries can generally reach 86℅, and China’s only 55℅ ~ 70℅. If the defoamer technology is adopted, and it is matched with the Chinese character, the coke tower height is reduced and the coke tower volume utilization rate is increased, the processing capacity of the delayed coking unit can be increased by more than 16%.

How to Defoamer for Delayed Coking work?

At present, silicone oil is generally used as a defoaming agent in delayed coking devices, and silicone oil with high molecular weight and high viscosity has a better effect. It is also useful as a defoamer made from a combination of propylene oxide and silicone oil. No matter which silicone oil is used, it must be diluted with kerosene or aromatic components in advance.

The defoamer is usually added from the top of the coke tower and is often injected with light diesel oil. The main purpose of carrying oil is to keep the injection pipeline clean and help the silicone oil to distribute on the foam. The typical amount of silicone oil is 2-20 micrograms / gram. There are a series of level gauges in the coke towers of foreign installations. When the foam layer reaches the lowest level, it starts to add defoamer and even switches the coke tower.

Due to the high temperature in the coke tower, a small amount of silicone oil will decompose into a series of volatile compounds, which will enter the coking gasoline, kerosene and diesel. Silicon has a toxic effect on hydrorefining catalysts. Therefore, the use of silica gel will affect the reprocessing of these distillates. At present, the development direction of delayed coking defoamers is to develop low-silicon or even silicon-free defoamers. By reducing the amount of silicone oil added to the coke tower, the silicon carried by distillate oil can be reduced.

For example, the processing capacity of the delayed coking unit of Jingmen Petrochemical Plant is 600,000 tons / year. Due to the large steam speed in the coke tower and the fractionation tower, the serious carry of coke powder causes the heat exchanger and air cooler to be blocked, and the excessively low coke powder in the fractionation tower seriously affects the safe and stable production and increases the maintenance cost; The catalyst in the hydrogen plant is poisoned and the life is shortened. Using INVINO-1062 defoamer (injection amount 55 ~ 80μg / g) produced by this plant, it can meet the process requirements, and the outlet temperature is increased from 495 ℃to 500 ℃, which promotes the cracking reaction and makes the light oil recover. The rate has improved and it is more economical.

Another example is the 1.1 million-ton / year delayed coking unit of Zhenhai Refining and Chemical Co., Ltd., for a period of time, the coke powder was seriously carried, which caused serious coke accumulation at the bottom of the fractionation tower. Since the use INVINO-1062 Defoamer, the coke powder carried by coking oil and gas has been greatly reduced, reducing the possibility of clogging of the coking radiation feed pump, the coking times of the fractionation tower are significantly reduced, the coking unit is in a benign circulation state, and the hydrogenation catalyst There was no recurrence of silicon poisoning.