Defoamer Performance Testing: Standard Methods and Procedures

Selecting the right defoamer or antifoam agent is crucial for countless industrial processes. But how do you objectively measure and compare defoaming performance? Reliable foam testing is essential for R&D, quality control, and choosing the most effective product for a specific antifoaming agents application. This guide outlines common defoamer testing procedures used in the lab, from standardized methods like the Ross-Miles foam test to dynamic evaluations, helping you understand foam testing methods and interpret results. INVINO utilizes robust testing protocols to ensure the quality and effectiveness of our antifoam solutions.

Common Foam Testing Methods in the Laboratory

Several standard and modified foam test procedures are employed:

Ross-Miles Foam Tester to Test Antifoam

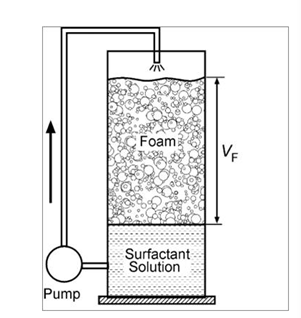

Dynamic Foam Testing (Air Sparging / Drum Test)

Foam Shake Test Method

- Principle: A simple, rapid foam test often used for quick screening or QC checks. It involves shaking a mixture of the foaming liquid and the defoamer/antifoam under standardized conditions.

- Procedure Outline: A defined volume of foaming medium and antifoam agent are placed in a sealed container (e.g., graduated cylinder). The container is shaken vigorously for a set time/number of shakes. Foam height is measured immediately after shaking and/or the time taken for the foam to collapse to a specific level is recorded. This is a common foam test procedure for detergents.

- Relevance: Provides a quick, comparative indication of knockdown efficiency, useful for initial screening or comparing similar defoaming agent examples.

Evaluating Defoaming Performance from Test Results

Simply running a foam test isn’t enough; interpreting the results correctly is key to understanding defoamer performance:

- Knockdown Time: How quickly does the defoamer reduce existing foam? (Relevant in Shake Test, Dynamic Test post-addition).

- Suppression Time / Persistence: How long does the antifoam prevent significant foam re-formation under continuous agitation or sparging? (Key metric in Dynamic Test).

- Maximum Foam Height: What is the highest level the foam reaches before being controlled? (Dynamic Test).

- **Foam Collapse Rate / Foam Stability: How quickly does the foam break down after agitation stops? (Shake Test, Ross-Miles). Defines the foam stability test procedure results.

- Dosage Efficiency: Comparing the above metrics at different defoamer concentrations to find the optimal dose.

Additional Factors Influencing Foam Testing Results

Accurate and repeatable foam analysis requires controlling variables:

- Temperature and pH: These significantly impact both the foaming tendency of the liquid and the stability/effectiveness of the antifoam reagent. Tests should be run at relevant process conditions.

- Long-Term Stability (of Defoamer): How long an antifoam remains effective after addition can be tested with prolonged dynamic tests. Some antifoams may lose efficacy over time.

- Compatibility: Interactions between the defoamer and other chemicals (surfactants, electrolytes, polymers) in the system can drastically alter foaming test results. Compatibility testing is crucial.

- Shear / Agitation: The type and intensity of mixing/agitation heavily influence foam generation and defoamer dispersion/stability. Test methods should mimic process shear where possible.

- Dosage & Dispersion: Ensure accurate dosing and adequate dispersion of the antifoam solution into the test medium.

INVINO: Expertise in Defoamer Testing and Solutions

At INVINO, we utilize standardized and customized foam testing methods in our dedicated foam testing laboratory to evaluate and develop high-performance defoamers. We understand the nuances of defoamer testing procedures and help clients select products proven effective for their specific needs.

(Conclusion)

Reliable foam testing is indispensable for understanding and optimizing defoamer performance. Utilizing appropriate methods like the Ross-Miles foam test, dynamic sparging, or foam shake tests, and carefully considering influencing factors, allows for informed selection of the best antifoam agent. INVINO combines robust foam testing capabilities with a range of effective defoamers to provide solutions you can trust.